Characteristics of our products

- The wave washer is a product that generates load by making deflection on it by curving a donut shaped plate.

- Higher load can be generated with narrower displacement (stroke) than coil springs.

- Since there is no distinction on the front and back, the product has no directionality.

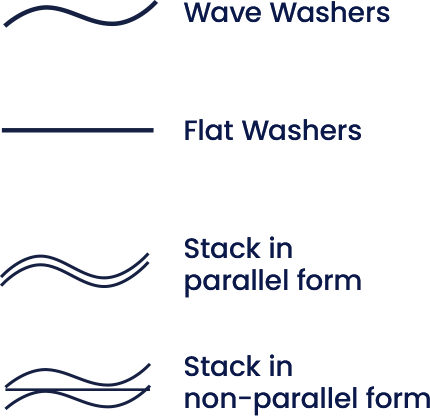

- Load and deflection can be modified by combining the washers.

- Combination examples

-

Stack in parallel form Larger load

Stack in non-parallel form Larger deflection - Type of wave washers

-

- For general use

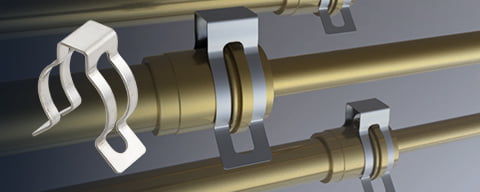

Preventing screws from loosening and mitigating abnormal noise and looseness by applying a specified level of preload. - For bearing

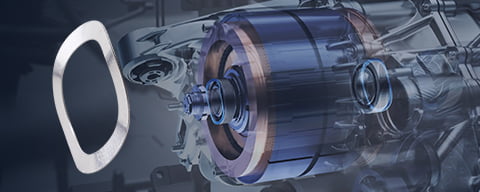

Wave washers for bearings. Applying preload to bearings effectively reduces vibrations and abnormal noise.

- For general use

- Main usage

-

- Automobile component parts

- Various motors

- Appliances

- Pre-load to bearings

- General industrial machineries

Specs and achievements

01 Products adopted

Through our commitment to high-quality production for both small and large quantities, we have accumulated over 50 years of successful adaptation to diverse customer applications.

02 High quality and precision products

Our products are widely embraced in the camera industry, precision motor industry, and various other sectors that demand stringent quality standards. We deliver high-quality, precision products through production techniques and rigorous quality control processes built on our extensive experience.

03 Large variety of products

Out of our extensive range of products, we can recommend the most suitable ones to meet our customers’ specific requirements.

- Product Adoption

-

- More than

- 550kinds

- For general use:

- 400+kinds

- For bearing:

- 150+kinds

- Delivery quantity per year

-

- More than

- 400million/year

- Feasible size for production

-

- Inner diameter:

- Φ3.5mm

- Outer diameter:

- Φ165mm

- Material grades and thickness

-

- Carbon spring steel: thickness

- 0.15–1.4mm

- Stainless steel: thickness

- 0.06–1.2mm

- Variation

-

We can propose various shapes.

04 Design and make prototype components for custom products

Rapid prototype development, offering design solutions swiftly and precisely, drawing from our expertise, our unique design approach, and customer requirements.

Download product data

- Specification list of wave washers · others(138.4KB)

- Types of Compressed Spring Washers (Characteristics and Instructions for Use)(73.7KB)

- Calculations for Compressed Spring Washers (Reference)(90.5KB)

- Prevention of Settling and Combined Use(89.1KB)

Specification list of products

Basic information

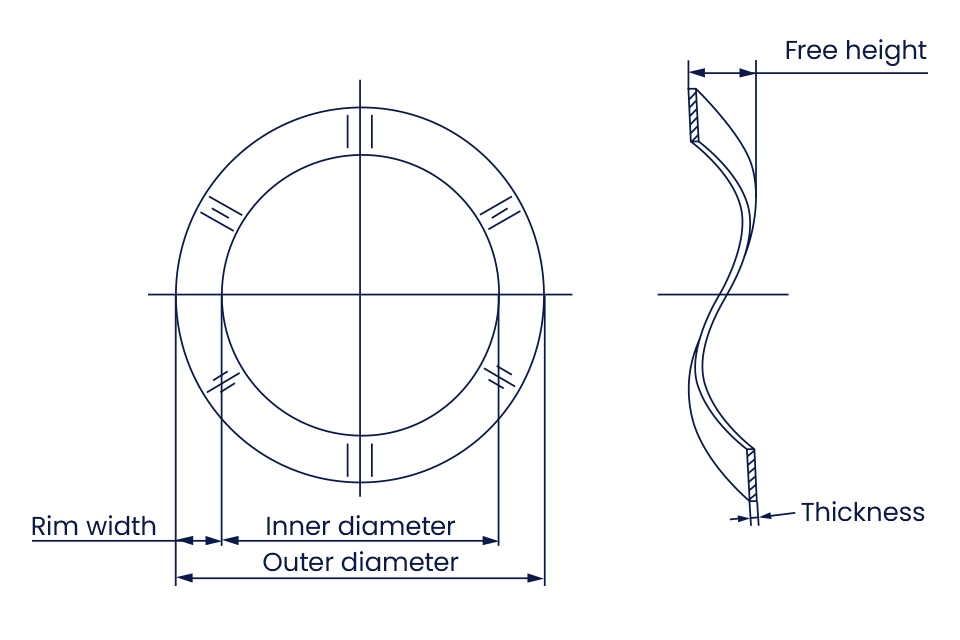

Dimensions

The dimensions of wave washers significantly impact their functionality, and it’s not solely about their size.

| Inner diameter | Inner diameter of product. Values will be larger than interference object of inner diameter. |

|---|---|

| Outer diameter | Outer diameter of product. Values will be larger than interference object of outer diameter. |

| Rim width | Wide: The load increases. Narrow: The load decreases. |

| Free height | This represents the total height of the wave washer, which is the dimension when the three waves are at the same height. |

| Thickness | Thick: The load increases. Thin: The load decreases. |

| The number of waves | Basically, the number of waves is 3. We can make 2 and 4 waves as well. |

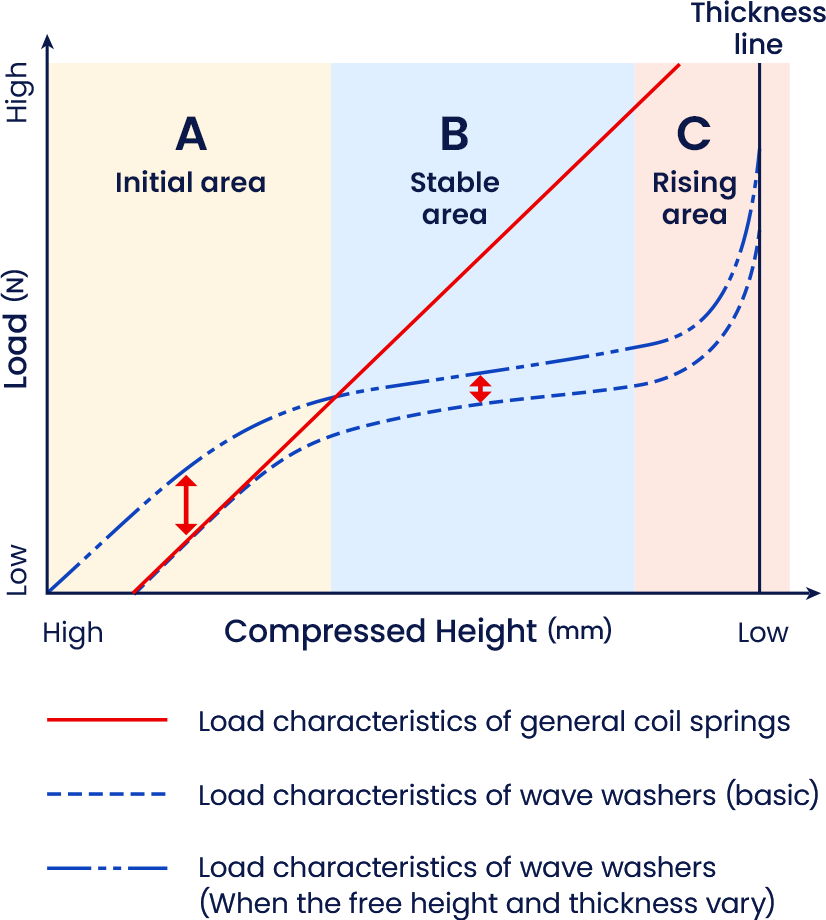

Load characteristics

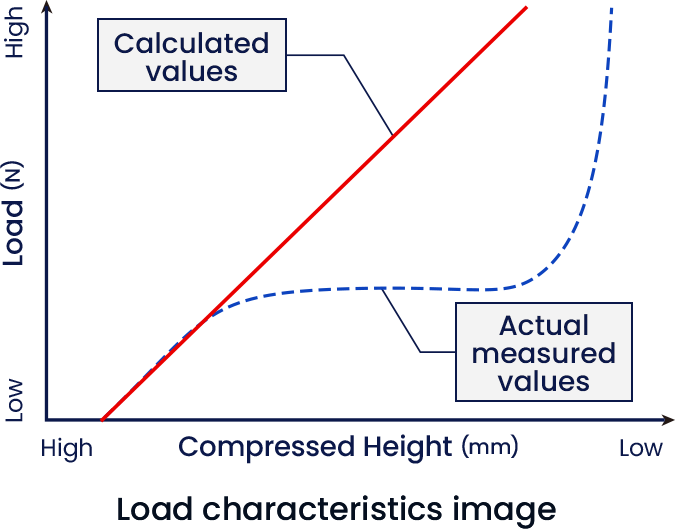

Because the load characteristics of wave washers follow curved lines and differ from those of typical coil springs, it is important to exercise caution and consider their specific application areas (see Fig. 1. Load characteristics image).

Some wave washers may not exhibit the curves described below distinctly in all application areas.

- A area

- Since it is easily influenced by fluctuation of free height, fluctuation of the load tends to be larger.

- B area

- Since it is not easily influenced by fluctuation of free height, fluctuation of the load tends to be smaller than A area. Also, the area of the usable height can be larger.

- C area

- Since it is close to the thickness (close to the total compression), the load rises sharply in this area.

Therefore, the load tends to be higher than other areas, and fluctuation of the load tends to be larger.

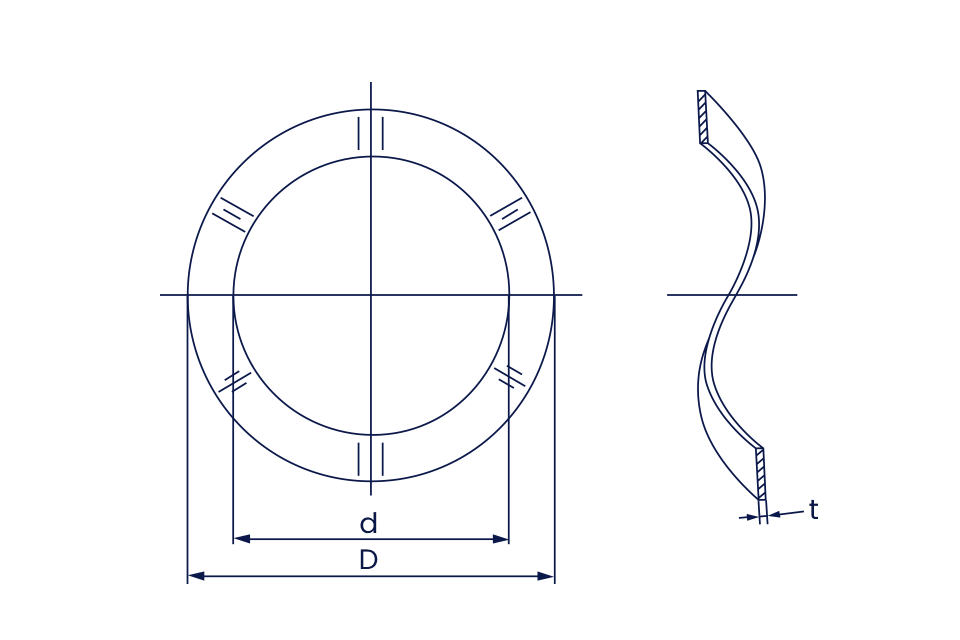

Calculation of load and stress

| P | Load (N) |

|---|---|

| S | Stress (N/mm2) |

| D | Outer diameter (mm) |

| d | Inner diameter (mm) |

| Dm | Average diameter (mm)[=(D+d)/2] |

| b | Rim width (mm)[=(D-d)/2] |

| t | Thickness (mm) |

| N | The number of waves |

| δ | Amount of deflection (mm) |

| E | Longitudinal elastic modulus (N/mm2) |

| π | Circumference ratio |

- Longitudinal elastic modulus of main materials (E)

-

Carbon spring steel 206,000 (N/mm2) Spring steel stainless 181,000 (N/mm2)

- Note(see Load characteristics image)

-

Since plastic deformation can not be taken into account with the load characteristics calculated by the formula, correlation of compression and load comes out as a straight line, but actual load characteristic will be a curved line due to influence of plastic deformation.

- Feel free to contact us if there are disparities between the calculated load values and the measured actual values.

- Results calculated by the formulas need to be verified with prototypes.

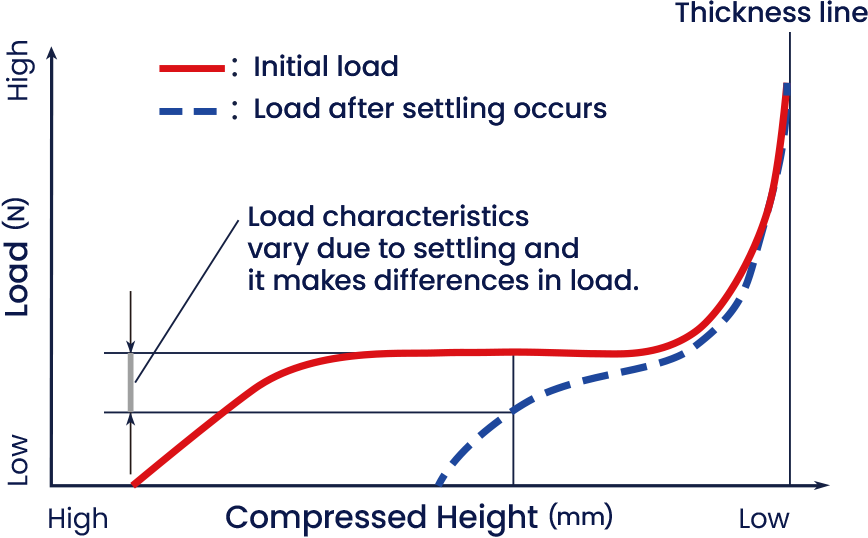

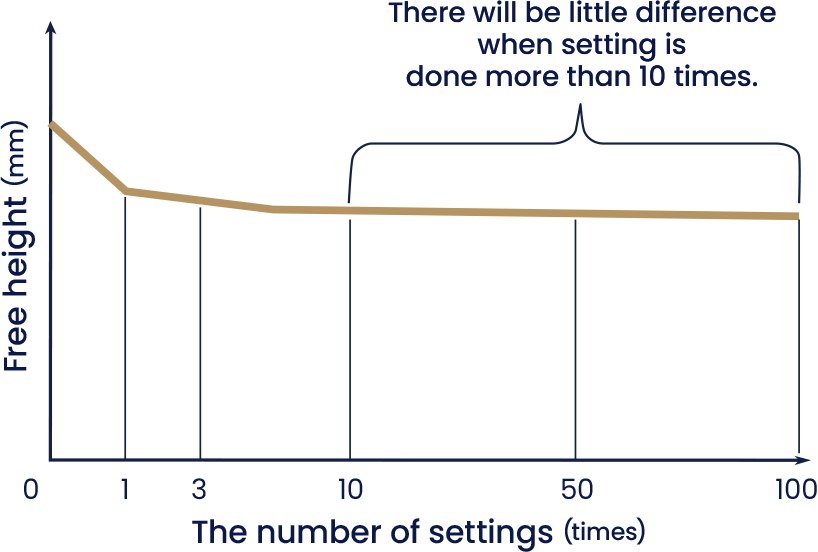

Prevention of settling

When the wave washers are used in conditions of 1 to 3 shown below, height will be lower than initial height and load will be varied under influence of settlement (Fig. 2).

By doing a setting before use can make the wave washers completely settled so that no more settling will occur (Fig. 3).

- When wave washers are subjected to repeated loading.

- When wave washers are utilized under creep conditions.

- When wave washers are compressed during assembly.

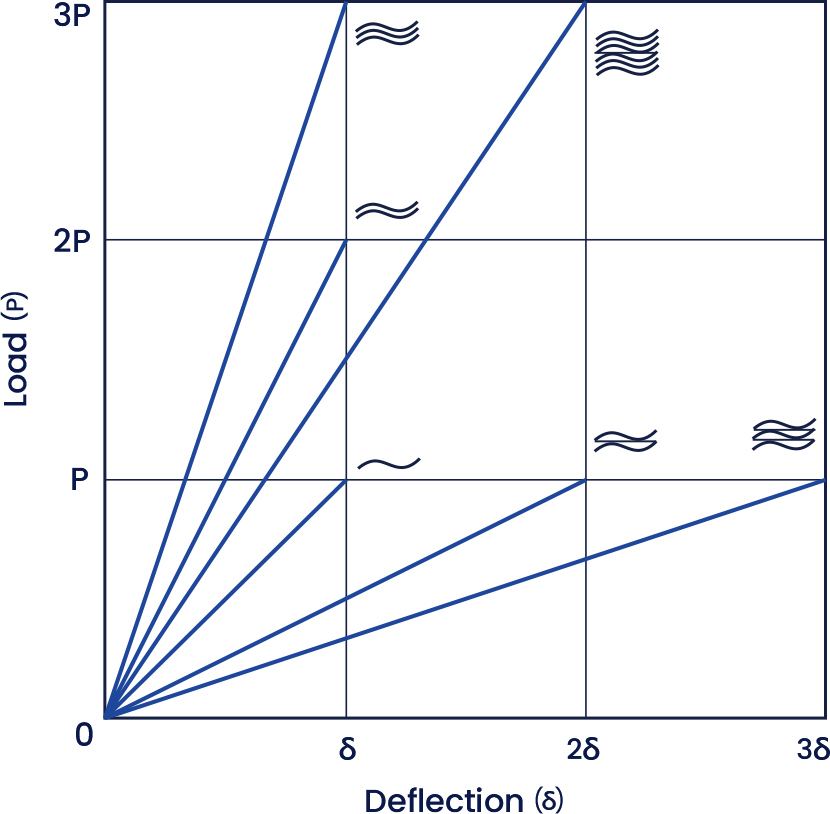

Combination

Load and deflection can be modified by combining the washers (Fig. 4).

However, these need to be combined with flat washers when these are stacked in non-parallel form only.

- To make the load larger with same amount of deflection as one piece is used, combine them in parallel form.

- To make the larger deflection at same load as one piece is used, combine them in non-parallel form.

- To make both deflection and load larger, combine them in both forms; parallel and non-parallel.

Notes for design and use

Reference points when designing

- To change the load by the larger amount

-

Adjust the thickness and the number of waves.

The load is directly proportional, and when you alter the thickness, it will vary cubically. Similarly, if you adjust the number of waves, it will change to the fourth power. (However, if the number of waves increases, the wave washer is prone to settle. Therefore, please consider a basic design with three waves.) - To change the load by the smaller amount

- Adjust the inner diameter (Rim width) and the amount of deflection. The load is proportional to the rim width.

Note

There are difference between the calculated and measured values for the formula of deflection and load.

When conditions like the diameters of outer and inner peripheries are substituted, it results in a linear equation relating deflection and load, which can be graphed as a linear relationship.

The actual load curve will not exhibit a straightforward linear pattern, but rather a curved one.