Quality related certifications

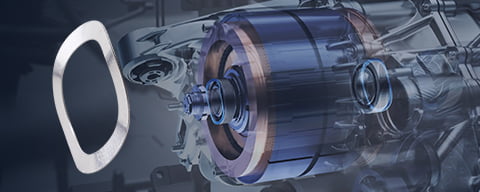

In addition to ISO 9001 certification for quality management systems, we have acquired IATF 16949*, an automobile related international quality standard. It makes us not only complying with quality management standards required in general, but we are also in compliance with special quality controls required to supply our products to North American and European automobile manufacturers. By managing heat treatment processes required for products with springiness based on CQI-9, our factories are certified as designated heat treatment factories by our customers.

We operate an environmental management system based on ISO 14001, ensuring compliance with RoHS and ELV regulations, eliminating environmentally hazardous substances, promoting recycling initiatives, and actively participating in environmental conservation activities.

- Please contact us for certifying organization, registration number and expiration date.

ISO 9001

-

- Ochiai Co., Ltd.

-

- Initial certification registration date

- December 8, 1998

- Scope of the registration

- Design, manufacture and sales of industrial fasteners

-

- Fukushima Ochiai Co., Ltd.

-

- Initial certification registration date

- November 22, 2002

- Scope of the registration

- Manufacturing industrial fasteners including snap rings and spring pins

-

- PT. OCHIAI MENARA INDONESIA

-

- Initial certification registration date

- September 6, 1999

- Scope of the registration

- Manufacture of T-nuts and precision parts for automotive by stamping machines, heat treatment and plating

-

- OCHIAI VIETNAM CO., LTD.

-

- Initial certification registration date

- January 6, 2014

- Scope of the registration

- Manufacture of industrial fasteners

ISO 14001

-

- Ochiai Co., Ltd.

-

- Initial certification registration date

- December 25, 2000

- Scope of the registration

- Design and manufacture of industrial fasteners

-

- PT. OCHIAI MENARA INDONESIA

-

- Initial certification registration date

- June 2, 2006

- Scope of the registration

- Manufacture of T-nuts and precision parts for automotive by stamping machines, heat treatment and plating

IATF 16949

-

- Ochiai Co., Ltd. (Head Office, Tokyo Sales Office, Chiba Factory)

-

- Initial certification registration date

- May 29, 2018

- Scope of the registration

- Manufacture of industrial fasteners

-

- OCHIAI VIETNAM CO., LTD.

-

- Initial certification registration date

- March 27, 2020

- Scope of the registration

- Manufacture of snap rings and wave washers

Identification management

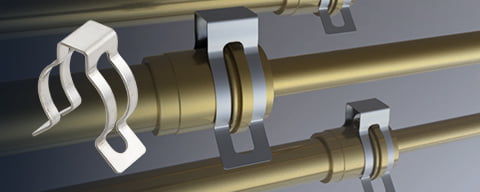

Because Ochiai produces a wide variety of products, the production process contains products that are so similar in shape that they are difficult to distinguish with the human eye, as well as products with only the slightest difference in size or shape. As a result, color-coded identification tags are attached to each box according to each process in the factory. Measuring equipment also have set inspection and alignment cycles, and the validity period of the inspection and alignment for each piece of equipment identified through color-coded stickers. In addition, should nonconforming products occur in a production process, they are identified and isolated in a dedicated storage area to ensure that they are not mistakenly shipped.

Inspection equipment

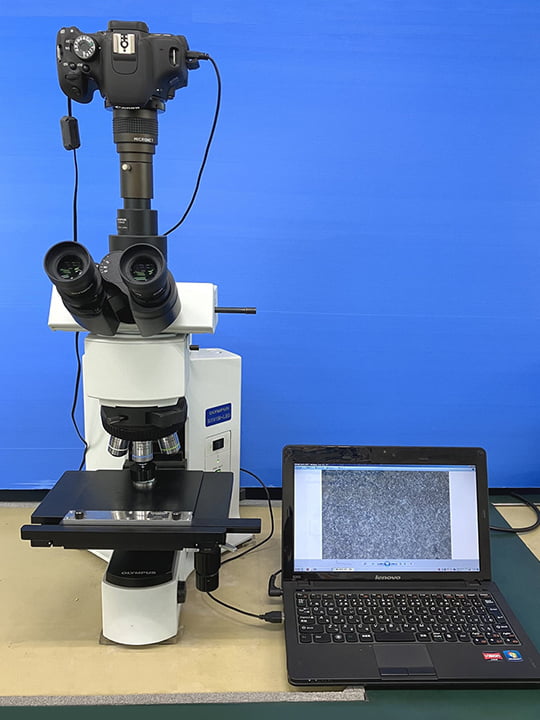

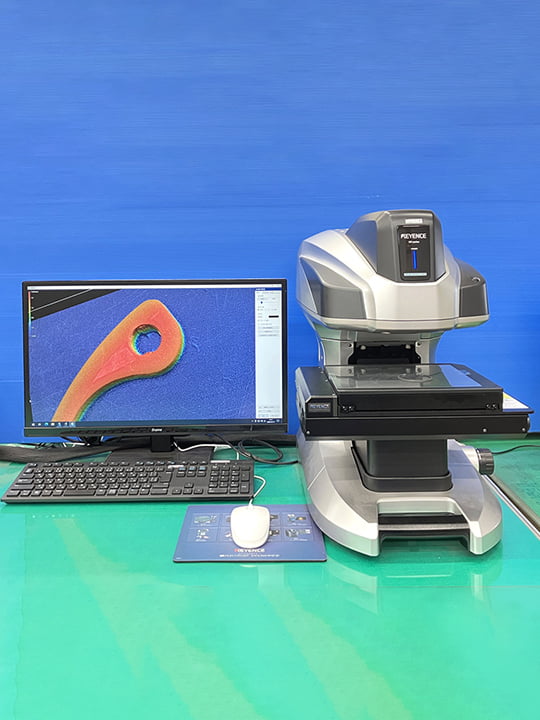

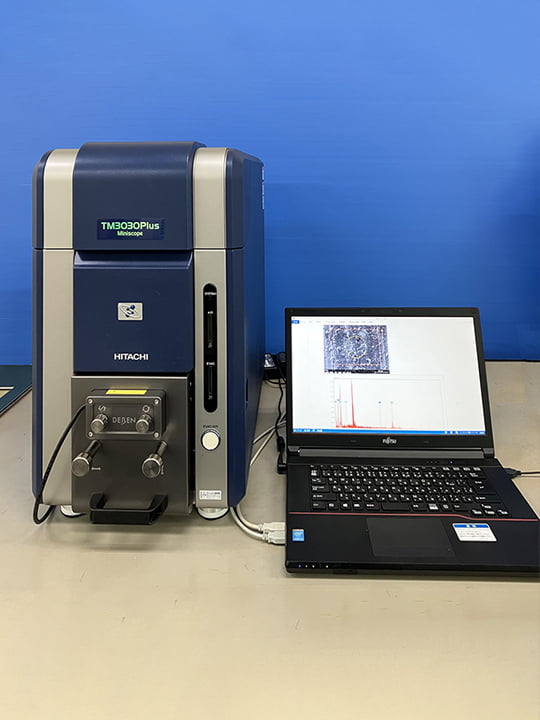

In order to meet the strict quality requirements of our customers, we have installed not only regular measuring equipment, but also the latest inspection equipment such as automatic image measuring equipment, metallurgical microscope, 3D measurement machines, load testing equipment and fluorescent X-ray film thickness meters to enable even more detailed measurements.

We employ a comprehensive quality assurance system, including a salt spray test machine for corrosion resistance assessment, microscopes for observing metallographic structures, and scanning electron microscopes (SEM) for analyzing broken products and measuring cleanliness in accordance with ISO 16232 and VDA 19 standards, ensuring the delivery of products with impeccable quality.

-

Load tester -

Automatic image dimension measuring machine -

Metallurgical microscope -

3D measurement machine -

Scanning electron microscope (SEM) -

Automatic image cleanliness measuring machine -

Fluorescent X-ray thickness meter